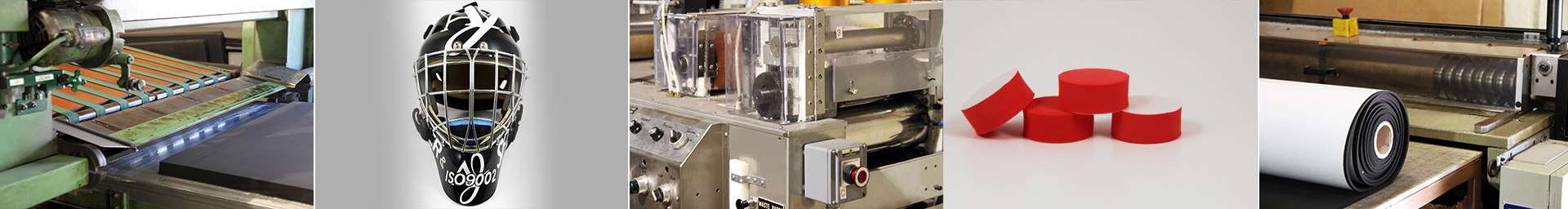

Custom Gaskets

In addition to our custom rubber seals, A.J. Rubber & Sponge Ltd. is capable of manufacturing custom gaskets from a variety of rubber, sponge or foam materials. Our custom gaskets are used in a diverse range of industrial and commercial industries, such as:

- Appliance manufacturing

- Automotive component fabrication

- Medical equipment production

- Aerospace & aviation

- Construction & general contracting

- Transportation

- Utilities & power generation

- HVAC

- Military / department of defense

- Furniture and décor production

- Packaging

- Sporting goods

- Tank car & ship building

- Electronic & hi-tech

- Pump & compressor manufacturing

- Engine production (gas, diesel & turbine)

- Chemical & petro-chemical

- Furnace & boiler manufacturing

- Pulp & paper processing

- Oil & gas drilling, production & refining industries

- Machinery, heavy equipment & transformer manufacturers

- Plumbing

- Small tool fabrication

- Foundry, steel & mining

- And many others!

A.J. Rubber & Sponge Ltds. custom gaskets are useful for many applications, such as water sealing, adhesion, sound absorption, cushioning, insulation, air sealing, vibration dampening, to name a few. For further information on the custom gaskets, or custom rubber seals, that we produce, please refer to our extensive list below, or give us a call with any questions you may have, and let us know just how we can assist you!

Neoprene rubber gaskets:

A.J. Rubber & Sponge Ltd. specializes in the manufacture of custom gaskets and seals, including custom rubber seals and neoprene rubber gaskets. Comprised of a durable synthetic material, our neoprene rubber gaskets suit many different commercial and industrial applications as sealants against toxic atmospheres and severe environmental elements. The neoprene we use in the manufacturing of our neoprene rubber gaskets is based on polychloroprene, and was developed as an oil resistant alternative to natural rubber. Our neoprene rubber gaskets are most commonly utilized in:

- The assembly and production of airplane, car, bus, trailer, truck and watercraft engines, clothing and electronic cases (please note that neoprene grommets are more suitable for the manufacturing of electrical connectors).

- Devices that are constantly exposed to abrasive chemicals.

- Environments that are exposed to extreme temperature ranges, including perpetual durations of extreme heat.

- Environments that are exposed to enormous pressure over lengthy periods of time.

Compared to their natural rubber gasket counterpart, A.J. Rubber & Sponge Ltds. neoprene rubber gaskets have a number of beneficial features:

- Tears and damage resistant due to flexing and/or twisting.

- Superior burn resistancy (as opposed to rubbers that are composed exclusively of hydrocarbon chains).

- Ozone, ultraviolet (UV) light, sunlight and other extreme weather condition resistant.

- Chemical and oil resistant (natural and synthetic).

A wide range of industrial and commercial businesses rely on A.J. Rubber & Sponge Ltds. neoprene rubber gaskets to help them with their permanent sealing requirements. We offer value-added services for the fabrication of our neoprene rubber gaskets, including but not limited to die cutting, “kiss” die cutting, and the application of pressure sensitive adhesive (PSA). To learn more about A.J. Rubber & Sponge Ltds. neoprene rubber gaskets, our other products such as custom rubber seals, or our other service offerings that include sheeting and slitting, please contact us and let us know about your unique application!

Closed cell silicone sponge custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. is renowned among commercial and industrial companies as a leading supplier of closed cell silicone sponge custom gaskets. Traditionally referred to as expanded silicone, our closed cell silicone sponge custom gaskets are available in thicknesses between 1/16" to 2", and are impermeable to moisture absorption under a variety of applications. Our closed cell silicone sponge custom gaskets possess many unique characteristics:

- Compared to solid silicone gaskets, they are extremely soft.

- Highly water resistant due to their closed cell structure.

- Hard density.

- Derived from an uncured silicone gum source which easily expands to a predetermined size during production.

Our silicone sponge custom gaskets are similiar to silicone foam custom gaskets, but the manner by which they are produced makes them unique to one another (information on our silicone foam custom gaskets can be found below). To discover just how A.J. Rubber & Sponge Ltds. closed cell silicone sponge custom gaskets, or custom rubber seals, can assist you in your industrial or commercial application, please contact us today.

Closed cell neoprene sponge custom gaskets:

A.J. Rubber & Sponge Ltd. specializes in the fabrication of custom gaskets and seals like custom rubber seals, neoprene rubber gaskets, and closed cell neoprene sponge custom gaskets. Our closed cell neoprene sponge custom gaskets can be used in a diverse range of industrial or commercial applications, and are most commonly used as sealants in devices that are constantly exposed to:

- Extreme chemicals such as oil (natural & synthetic), gasoline, acid etc.

- Severe weather elements such as ultraviolet (UV) light radiation, rain, snow, hail, sleet, direct sunlight, ozone, etc.

- Other unstable forces

A.J. Rubber & Sponge Ltd. employs die cutting, “kiss” die cutting and pressure sensitive adhesive (PSA) application to the production of our closed cell neoprene sponge custom gaskets. Our closed cell neoprene sponge custom gaskets fall within a family of synthetic rubbers that possess many advantageous features, including:

- Temperature operating ranges of -56.7°C to 93.3°C (-70° F to + 200° F).

- Resistant to tears or damage caused by flexing and/or twisting.

- Superior heat resistance making them ideal for industrial or commercial applications exposed to extremely high temperatures over long periods of time.

- Suitable for long term outdoor applications such as weather stripping or electrical enclosures.

- Resistant to ozone, ultraviolet light, sunlight and many other extreme weather elements

- Much better at resisting burning than rubbers that are composed exclusively of hydrocarbon chains.

We have provided a number of industrial and commercial businesses with closed cell neoprene sponge custom gaskets to help them tackle issues requiring sealing under high temperatures and/or enormous pressures over lengthy periods of time. Much like our custom rubber seals, our closed cell neoprene sponge custom gaskets are engineered to stay firmly in place and provide long-lasting permanent sealing for various applications within the following industries:

- Oil & gas

- Automotive manufacturing

- Clothing production

- Electronics fabrication

- Medical equipment manufacturing

- Aviation & aerospace

- Military equipment production

- Engine assembly for airplanes, trucks, cars, buses, trailers and watercraft

- And many others

For more information on our closed cell neoprene sponge custom gaskets, or our custom rubber seals, please give A.J. Rubber & Sponge Ltd. a call today. For technical data pertaining to our closed cell neoprene sponge custom gaskets, please click on the following links:

AJ-42 spec sheet AJ-43 spec sheet AJ121 spec sheetClosed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets:

Besides custom rubber seals, A.J. Rubber & Sponge Ltd. manufactures closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets. Our closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets can be used in a variety of outdoor applications such as weatherproofing or electrical enclosures. Some of the benefits that our EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets offer industrial or commercial enterprises for their unique applications are:

- Superior resistance to oxidation and ozone

- Exemplary aging properties and compressibility

- Temperature operating ranges are from -51.1°C to 98.9°C (–60° F to 210° F)

For further information on A.J. Rubber & Sponge Ltds. closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets, or our custom rubber seals, please contact us today. For technical data on our closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets, please click on the following links:

EPDM-41 spec sheet EPDM-43 spec sheetClosed cell vinyl nitrile sponge custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. also manufactures closed cell vinyl nitrile sponge custom gaskets. Our closed cell vinyl nitrile sponge custom gaskets are comprised of cells that resemble balloons which seal in gas as well as prevent moisture from escaping (considering the walls of the gaskets cells remain intact). This unique property of closed cell vinyl nitrile sponge material lends to its commonly used name, “expanded rubber”. Other unique properties include:

- Application temperature range of -40°C to 82°C (-40°F to 180°F).

- Slightly lower density profile than most other closed cell sponge products

- Slightly higher water absorption properties than closed cell neoprene rubber gaskets

Please get in touch with A.J. Rubber & Sponge Ltd. to learn more about the closed cell vinyl nitrile sponge custom gaskets, or custom rubber seals, that we fabricate. For technical data on our closed cell vinyl nitrile sponge custom gaskets, please click on the following link:

AJ310 spec sheetClosed cell ECH (epichlorohydene) sponge custom gaskets:

Just like our custom rubber seals, A.J. Rubber & Sponge Ltds. closed cell ECH (epichlorohydene) sponge custom gaskets can be applied to a diverse range of commercial and industrial processes. Our closed cell ECH (epichlorohydene) sponge custom gaskets have many unique properties, including:

- Capable of being exposed to continuous temperatures of up to 150°C (300°F),

- Resists damaging effects from light oil (natural and synthetic), and fuel

- Resists various types of harsh weather

Our closed cell ECH (epichlorohydene) sponge custom gaskets are frequently used in the automotive manufacturing industry, usually incorporated into under-the-hood applications. Get in touch today with A.J. Rubber & Sponge Ltd. to further explore our closed cell ECH (epichlorohydene) sponge custom gaskets, or custom rubber seals. For technical data on our closed cell epichlorohydene sponge custom gaskets, please click on the following link:

aj ECH spec sheetSBR (styrene butadiene rubber) sponge custom gaskets:

Besides custom rubber seals, A.J. Rubber & Sponge Ltd. manufactures SBR (styrene butadiene rubber) sponge custom gaskets. Otherwise known as GRS and buna-S or buna S gaskets, we fabricate our SBR (styrene butadiene rubber) sponge custom gaskets for a wide range of applications including:

- Pneumatic tire and tube manufacturing

- Heel and sole production for various footwear

- Many other commercial or industrial applications

In spite of their durability, A.J. Rubber & Sponge Ltds. SBR (styrene butadiene rubber) sponge custom gaskets are not very resistant to sunlight, ozone, rain or other extreme weather elements, making them impractical any type of electrical application. However, our SBR (styrene butadiene rubber) sponge custom gaskets have a wide range of beneficial properties, such as:

- Excellent abrasion resistance.

- Superior stability over a range of environments.

- Resistant to fats, minerals, oils (natural and synthetic), aliphatic hydrocarbons, aromatic hydrocarbons and chlorinated hydrocarbons.

- Transitions into glass at a temperature of approximately -55°C (131°F).

- Have a recommended temperature range of -40°C to 100°C (-40°F to +212 °F).

- Have an elongation percentage of between 450–500%).

For more information about A.J. Rubber & Sponge Ltds. SBR (styrene butadiene rubber) sponge custom gaskets, or our custom rubber seals, please give us a call. For technical data on our SBR (styrene butadiene rubber) sponge custom gaskets, please click on the following link:

AJ8511 spec sheetSilicone foam custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. also manufactures silicone foam custom gaskets (otherwise known as foam silicone custom gaskets within the cellular foam, rubber and sponge products industry). Some of the benefits of A.J. Rubber & Sponge Ltds. silicone foam custom gaskets are:

- UV (ultraviolet) light and ozone resistant due to the inorganic backbone of their molecular structure, which is the foundation for their long term performance.

- Wide temperature operating range of approximately -53°C to 201°C (-65°F to 395°F).

- Resistant to decay by aging, or degradation from sunlight.

- Superior compression set resistance (the materials ability to rebound to its original thickness upon being compressed).

- Intrinsically flame resistant.

A.J. Rubber & Sponge Ltd. can provide commercial and industrial businesses with two different types of silicone foam custom gaskets:

Closed cell silicone foam custom gaskets

These silicone foam custom gaskets work well as environmental and moisture seals, as they are extremely durable and resistant to environmental fluctuations due to silicones high density, low toxicity and low compressive forces.

Open cell silicone foam custom gaskets

These silicone foam custom gaskets are produced via a specialized process using liquid silicone ingredients as the base material. Open cell silicone foam custom gaskets are lightweight, low in density, and may allow moisture to escape, so they tend to be best applied as shock or vibration gaskets such as those found in automotive applications.

A.J. Rubber & Sponge Ltds. silicone foam custom gaskets can be used to seal in liquids in high-pressure applications, or to block out light, air and dust in low-pressure environments making them ideal for use in industrial buildings, production facilities, manufacturing plants and other general industrial applications. With adequate coverage, achieving long term moisture or weather seals with A.J. Rubber & Sponge Ltds. silicone foam custom gaskets is possible, thanks to recent technology advancements in the custom gasket manufacturing industry.

Regardless of what type of silicone foam custom gasket you choose for your one-of-a-kind application, A.J. Rubber & Sponge Ltd. is able to apply a vast range of pressure sensitive adhesives (PSA) to all silicone foam custom gaskets that we produce. Our silicone foam custom gasket manufacturing process includes:

- “Kiss” die cutting

- Horizontal splitting

- Roll slitting

- Custom assemblies

- Die cutting

Our silicone foam custom gaskets are similiar to silicone sponge custom gaskets, but the manner by which they are produced makes them unique to one another (information on our silicone sponge custom gaskets can be found above). To learn more about the silicone foam custom gaskets, or custom rubber seals, that A.J. Rubber & Sponge Ltd. manufactures, please get in touch with us today.

Acoustic foam custom gaskets:

Just like our custom rubber seals, A.J. Rubber & Sponge Ltds. acoustic foam custom gaskets can be applied to a variety of uses in a wide range of industrial and commercial environments, especially those involving noise reduction, thermal insulation and/or vibration control (such as in the automotive assembly industry). Our acoustic foam custom gaskets are easily produced in both plain and pressure sensitive adhesive (PSA) backed formats (single or duplicate sides). The thickness of our acoustic foam custom gaskets ranges from:

- 1mm up to 100mm thick - without lamination / pressure sensitive adhesive (PSA)

- Greater than 100mm - with lamination / pressure sensitive adhesive (PSA)

- To learn more about A.J. Rubber & Sponge Ltds. acoustic foam custom gaskets or custom rubber seals, please get in touch with us today.

Polyurethane foam custom gaskets:

Polyurethane foam is an economical type of open cell flexible foam material that is commonly incorporated in the manufacturing process of custom gaskets. Besides custom rubber seals, A.J. Rubber & Sponge Ltd. fabricates polyurethane foam custom gaskets for use in commercial or industrial applications including, but not limited to:

- Moisture sealing

- Thermal & acoustic insulation

- Cushioning

- Dust sealing

Our polyurethane foam custom gaskets are readily available with pressure sensitive adhesive (PSA) backing as an option. Contact A.J. Rubber & Sponge Ltd. to learn more about our polyurethane foam custom gaskets, or our custom rubber seals. For technical data on our polyurethane foam custom gaskets, please click on the following link:

AJ702-2 spec sheetMicrocellular urethane foam custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. also manufactures microcellular urethane foam custom gaskets for a number of commercial and industrial uses. Our microcellular urethane foam custom gaskets provide excellent compression set resistance and are very resilient, providing a gasket seal that will not break down over extended use. These traits of our microcellular urethane foam custom gaskets allow them to be utilized in a wide variety of applications, and will perform very well under the temperature range of -40°C -90°C (-40°F to 194°F). For more information on A.J. Rubber & Sponge Ltds. microcellular urethane foam custom gaskets, or our custom rubber seals, please contact us today.

Cross-linked polyethylene foam custom gaskets:

Just like our custom rubber seals, A.J. Rubber & Sponge Ltds. cross-linked polyethylene foam custom gaskets can be used in a wide range of industrial and commercial environments. Our cross-linked polyethylene foam custom gaskets have many beneficial features making them ideal for a large variety of industry-specific applications:

- Superior thermal insulating

- Excellent chemical resistance

- Smooth surface

- Excellent consistency

- Ideal gauge control

- Resistant to high temperatures

- Low water absorption

Contact A.J. Rubber & Sponge Ltd. to learn more about the cross-linked polyethylene foam custom gaskets, or custom rubber seals, that we manufacture. For technical data on our cross-linked polyethylene foam custom gaskets, please click on the following link:

AJ199 spec sheetSBR (styrene butadiene rubber) custom gaskets:

Besides custom rubber seals, A.J. Rubber & Sponge Ltd. produces SBR (styrene butadiene rubber) custom gaskets for use in various commercial and industrial applications. SBR (styrene butadiene rubber) custom gaskets are commonly incorporated into the manufacture of pneumatic tires, tubes, footwear heels and soles, as well as for many other industrial and commercial uses. Also referred to as GRS, buna-s or buna s, SBR (styrene butadiene rubber) is a versatile material that features the following unique properties:

- Transitions into a glass-like substance at a temperature of approximately -55°C (131°F) (also referred to as the “glass transition temperature”).

- Has a typical elongation percentage of approximately 500%.

- Has a recommended temperature operating range of -40°C to 100°C (-40°F to +212 °F).

As SBR (styrene butadiene rubber) custom gaskets are not resistant to ozone, sunlight, rain, sleet, snow or other harsh weather elements, they are not recommended for use in any type of electrical application. To learn more about A.J. Rubber & Sponge Ltds. SBR (styrene butadiene rubber) custom gaskets, or custom rubber seals, please contact us today.

Nitrile rubber custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. also manufactures nitrile rubber custom gaskets for a variety of industrial and commercial applications. Our nitrile rubber custom gaskets physical and chemical properties can vary depending on the composition of the specific acrylonitrile species involved. As an example, the higher the concentration of acrylonitrile in the polymer, the higher the nitrile rubber custom gaskets resistance to oils will be. This particular property, however, can compromise the flexibility of the custom rubber gasket and make it more rigid.

Also referred to as buna-n rubber, nitrile rubber belongs to a family of synthetic rubber custom gasket materials that are comprised of a copolymer of acrylonitrile and butadiene. Nitrile rubber custom gaskets tend to be highly resistant to:

- Grease

- Oil (natural & synthetic)

- Gasoline

- Diesel

- Other types of abrasive chemicals

A.J. Rubber & Sponge Ltds. nitrile rubber custom gaskets resistance to these harsh substances makes them an ideal choice for use in applications where components are exposed to corrosive chemicals on a regular basis. We do not manufacture nitrile rubber o-rings or nitrile rubber molding components, nor do we employ the trade names Eroprene, Nipol or Krynac. Our Hamilton, Ontario based production facility is fully capable of custom fabricating nitrile rubber custom gaskets of all shapes and sizes using our die cutting presses and other related machinery.A.J. Rubber & Sponge Ltd. has over 50 years of experience manufacturing nitrile rubber custom gaskets for use across a wide variety of applications and industries. To learn more about our nitrile rubber custom gaskets capabilities, or our custom rubber seals, please contact us today.

CI (cloth inserted) rubber custom gaskets:

Just like our custom rubber seals, A.J. Rubber & Sponge Ltds. CI (cloth inserted) rubber custom gaskets can be used in a variety of industrial and commercial environments. CI (cloth inserted) rubber custom gaskets are best suited for applications where hot or cold water and gases are being transferred, such as:

- Water meters

- Control devices

- Batching devices

- Regulators

- Booster pumps

- Diaphragms

A.J. Rubber & Sponge Ltds. CI (cloth inserted) rubber custom gaskets are composed of a rubber sheet material that is reinforced with one or more plies of cloth (polyester, nylon, cotton and/or fiberglass), for added strength and stability. This makes our CI (cloth inserted) rubber custom gaskets ideal for use in flanged custom gasket applications requiring mechanical fastening, or where mechanical tension due to compression loads is high.

Get in touch with A.J. Rubber & Sponge Ltd. to learn more about the CI (cloth inserted) rubber custom gaskets, or custom rubber seals, that we produce.

Military specification rubber custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. produces military specification rubber custom gaskets. We are very proud of our position as a defense contractor for the Canadian and U.S. military Departments of Defense, and other global counterparts. We custom manufacture a variety of military specification rubber custom gaskets for use in sealing devices that meet military standards and requirements. These standards are designed to ensure that elastomeric materials support military missions by meeting necessary performance requirements.

Military specification rubber custom gasket suppliers are usually familiar with these standards, but may not fully understand how the details of a particular gasket specification can affect manufacturing and purchasing decisions from a military standpoint. This is where A.J. Rubber & Sponge Ltd. comes in. As our technology advances, so do the design and production methods of military specification rubber custom gaskets, ensuring that they have the ability to withstand aggressive environments. Military specification rubber custom gasket performance is affected by drastic fluctuations in temperature, and this is something that needs to be considered at the time of choosing appropriate gasketing materials. A.J. Rubber & Sponge Ltd.’s military specification rubber custom gaskets are capable of being used in environments with continuous service temperatures as low as -51ºC to as high as 200ºC (-60ºF to 401ºF).

We support North American defense by supplying custom rubber seals, military specification rubber custom gaskets, or any other type of military specification gaskets that may be required. Please contact us to learn more about the military specification rubber custom gaskets that A.J. Rubber & Sponge Ltd. manufactures.

Silicone rubber custom gaskets:

Besides custom rubber seals, A.J. Rubber & Sponge Ltd. fabricates silicone rubber custom gaskets for use in a variety of commercial and industrial applications for a few important reasons:

- Due to silicone rubbers inert property, silicone rubber custom gaskets will not react with most chemicals in any given environment.

- Silicone rubber custom gaskets are highly resistant to environmental factors such as ozone exposure, ultraviolet (UV) radiation, heat or any other factor contributing to the silicone rubber custom gaskets aging process.

- Silicone rubber custom gaskets are an excellent insulator of electricity.

- Silicone rubber custom gaskets are superior to conventional rubber gaskets in terms of tensile strength, elongation, tear strength and compression set.

- Silicone rubber custom gaskets designed to be operational between extreme temperatures of -55°C and +300°C (-67°F and 572°F).

Silicone rubber custom gaskets contain a "backbone" of silicon-oxygen links as opposed to the carbon to carbon (C to C) backbone found in traditional, organic rubber, making it a very versatile custom gasket for use in many different applications:

- Molding applications in the medical industry.

- Production of implants.

- Electrical connector insert applications in electronics manufacturing.

- Silicone gum in the compression molding process.

- Any high altitude / high temperature sterilization environment in the aerospace or medical industries.

Please contact A.J. Rubber & Sponge Ltd. to learn more about the silicone rubber custom gaskets, or custom rubber seals that we manufacture.

EPDM (ethylene propylene diene monomer) rubber custom gaskets:

In addition to custom rubber seals, A.J. Rubber & Sponge Ltd. has the expertise and the ability to die cut EPDM (ethylene propylene diene monomer) rubber custom gaskets to exact specifications for use in any industrial or commercial application. Our EPDM (ethylene propylene diene monomer) rubber custom gaskets can withstand temperatures ranging from -50°C to 150°C (-58°F to 302°F), and will function as a source of noise reduction / acoustic insulation, especially good for use in the automotive industry. EPDM (ethylene propylene diene monomer) rubber custom gaskets are an excellent source of producing gasket sealing against harsh atmospheric elements including sunlight, ozone, ultraviolet (UV) light exposure, wind, rain or other severe weather conditions.

Best known for their superior resistance to harsh and toxic chemicals, EPDM (ethylene propylene diene monomer) rubber custom gaskets are most ideal for sealing environments that are not exposed to any type of:

- Aliphatic hydrocarbons

- Halogenated solvents

- Concentrated acids

- Oils (synthetic or natural)

- Gasoline

- Kerosene

- Aromatics

Should you require additional information on the EPDM (ethylene propylene diene monomer) rubber custom gaskets, or custom rubber seals that A.J. Rubber & Sponge Ltd. manufactures, please contact us today.

Polyethylene Gaskets:

Just like our custom rubber seals, A.J. Rubber & Sponge Ltds. polyethylene gaskets can be applied to a wide range of industrial or commercial atmospheres. We are capable of die cutting, kiss die cutting and applying pressure sensitive adhesive (PSA) to our polyethylene gaskets which possess a high degradation rate. With more than 50 years of experience in the custom gasket and seal manufacturing industry, we have learned that polyethylene gaskets are best suited for the following applications:

- Where atmospheric temperatures remain consistently low (although they are able to effectively perform in moderate temperature environments).

- As seal liners around doors, windows and other openings.

- In the assembly of large engines, for airplanes, trucks, cars, buses, trailers and various types of watercraft.

- For sealing apparatus that are under extreme pressure, such as electrical appliance doors.

- Any other application where the seal is often broken and re-established.

To further explore A.J. Rubber & Sponge Ltds. polyethylene gaskets or custom rubber seals, please get in touch with us. Should you require technical data on our polyethylene gaskets, please click on the following link:

AJ199 spec sheet